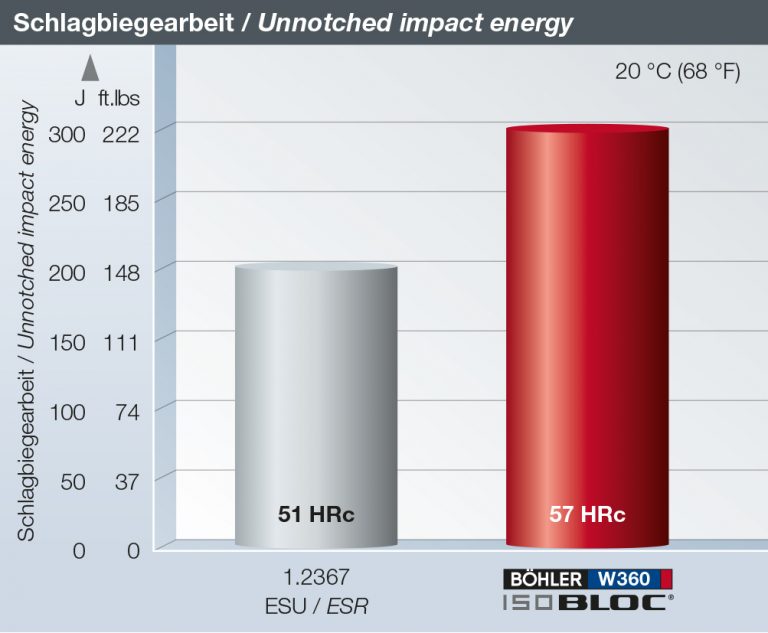

BÖHLER W360 ISOBLOC is a material produced by the electroslag remelting process (ESR), which has been specially adapted for use at high tool hardnesses in the range of 51-57 HRC. Although the steel can be classified as a 5% chromium steel, the increased carbon and

molybdenum content coupled with state-of-the-art manufacturing technology ensures that BÖHLER W360 ISOBLOC still shows a very good toughness and an exceptionally good thermal resistance, even at high hardness levels. These properties make the steel the perfect choice for smaller components in the die casting sector (e.g., mold inserts, cores, core pins, ejector pins, etc.). The material also is frequently the preferred choice for closed-die and open-die forging tools due to its high wear resistance. Because of this excellent wear resistance and the high toughness, BÖHLER W360 ISOBLOC is also frequently used for cold work applications and as a molding material for plastic injection molds. The Steel also is available as powder material for metal-3D-printing under the brand name BÖHLER W360 AMPO.

| 熱間強度 | 熱間靭性 | 耐熱摩耗性 |

|---|---|---|

|

|

|

|

| 市中材料 |

|---|

| BÖHLER patent |

| C | Si | Mn | Cr | Mo | V | |

|---|---|---|---|---|---|---|

| 0.50 | 0.20 | 0.25 | 4.50 | 3.00 | 0.60 |

Information on 長尺材 ) Presented data refer exclusivly to long products. Please observe the detailed explanations at the end of the data sheet (pdf).